Shipper | Research and reports

Layered security keeps cargo and freight safe, secure and theft-free

Schneider provides a layered security solution in keeping your cargo safe from tender and pickup to transit and delivery.

A holistic approach to freight security in an unsafe world

There is no doubt that supply chains are complex, and this complexity creates vulnerability. Unfortunately, we live in an age where a growing number of people are looking to exploit these vulnerabilities, resulting in an unacceptable level of cargo thefts. The thieves are getting smarter, more aggressive and more selective in their targets. They now excel at identifying the loads that carry high-value goods. Plus, their techniques for pulling off the heist have grown so sophisticated that it takes a lot more than a simple lock to stop them.

For some shippers, the cost of the products stolen may be the smallest part of the issue. Many shippers, including food and pharmaceutical manufacturers, are at risk of losing even more when it comes to product safety, brand reputation and lost opportunity at the store shelf. In fact, given the regulations from the FDA and other agencies, one successful theft could result in a full product recall that will exponentially increase the cost to any organization.

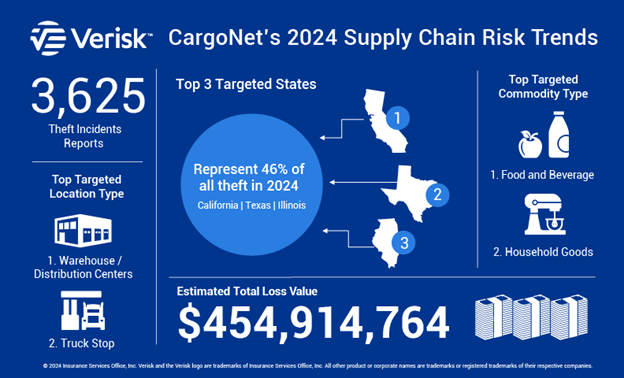

The transportation industry experienced record-breaking cargo theft activity in 2024. According to CargoNet, incidents were up 27% from 2023; the estimated average value per theft increased to $202,364 compared to $187,895 in 2023. Despite the rise of theft-by-deception, traditional cargo theft methods remained widespread. Data indicates a growing and increasingly sophisticated threat landscape in cargo theft, with criminal enterprises showing tactical adaptability in their methods and target selection. Looking ahead to 2025, CargoNet expects these trends to persist, with organized criminal groups likely to continue aggressively targeting supply chain vulnerabilities. Taking advantage of opportunities to enhance security practices remains key.

Below are the 2024 supply chain risk trends by CargoNet.

Shippers often assume their carriers and intermodal providers are doing everything possible to prevent cargo theft. That assumption, in itself, is dangerous. There are countless opportunities to reduce risk and secure a supply chain throughout the life of a load – whether it’s moving on the road or on the rail. Shippers who are aware of these measures can, and should, hold their carriers accountable for executing tested best practices.

Defining freight and cargo security actions

Carriers with a culture that revolves around reducing risk in every area of the business have shown a decline in freight thefts – some by as much as 75% in recent years.

For some carriers, the solution to improving security is as simple as moving high-value freight via expedited team services. More sophisticated carriers know that creating a culture of safety and security (for drivers and freight), continuous attention to basic security practices and a commitment to supply chain process refinement also play a role in keeping freight safe and secure.

Security actions generally fall into three categories:

- personnel security,

- information security, and

- physical security.

To better demonstrate the overlap of these dimensions and the integration required for a secure move, let’s break them down by type of move (truckload and intermodal) and phase of movement (load tender, pickup, transit, and delivery).

Freight at rest is freight at risk of theft

Moving truckload freight securely

Nearly 64% of freight moved across the border makes its way from point of origin to point of destination (and sometimes, many places in between) via truck. That’s a lot of freight to track and keep safe, but it can be done.

Load tenders: A secure cargo haul begins before the load even moves

A secure move begins before the load even moves: at the point when the shipper tenders the freight to the chosen carrier.

- The carrier must communicate well and ask questions to gain the right information about the load’s contents.

- If the load is determined to be of high value (usually $100,000 or more) or a commodity typically identified as highly “fence able” (e.g., pharmaceuticals, electronics, tobacco, alcohol, cosmetics), it should immediately trigger a special series of events.

- The driver assigned to the load must have enough service hours available, and enough fuel, to run at least 200 miles after pickup. Thieves target loads coming out of facilities and will track them for significant distances. If the driver stops 10 miles away, the truck has an increased risk of being hit.

- The driver should be informed that this is a high-value load and requires special attention. Any driver assigned to a high-value load should participate in a three-way call with his or her manager and the customer service representative to review the details of the load and the steps that must be taken to ensure a safe and secure delivery.

- The shipper should be offered team service for the load. This means two drivers will be with the load for the duration. While one sleeps, the other drives – meaning the load is rarely at rest. Freight at rest is freight at risk.

Practicing secure practices also at shipment pickup

Secure deliveries require secure practices at pickup.

- The carrier should develop an understanding of the shipper’s facilities and have full confidence that the shipper is committed to protecting the freight at the point of origin. If there is any concern about the safety of a load at pickup, the carrier can work with the shipper to create a safer situation. For example, if the carrier notices that a particular shipper tends to load late – putting the driver(s) at the tail end of his or her service hours and unable to run the required 200 miles from pickup to first stop – the carrier should educate the shipper about the inherent risk and work out a better solution.

- The shipper should be on the lookout for fictitious pickups, that is, pickups that appear to be legitimate but aren’t. Thieves might gain knowledge of a load through insider intel or by observing your operations. They learn enough to sound convincing, disguise their truck, and impersonate a legitimate carrier coming to pick up your load. To prevent fictitious pickups, practice a layered security approach, including operations security that can prevent information from falling into the wrong hands, and become a member of CargoNet. You should always validate who is picking up your load and monitor the truck with GPS tracking to make sure the truck that has arrived is actually the one that should be picking up your load.

- The driver(s) should fuel up before arriving at the shipper’s facility, thereby eliminating any risk that comes with stopping to fuel soon after leaving with a loaded trailer or container.

- The driver(s) must complete a thorough inspection of the truck and trailer or container prior to pickup, thereby reducing the risk of a breakdown in transit.

- While at the shipper’s facility, the driver(s) must adhere to any and all security procedures required by the shipper.

- In the case of a live load, several carriers recommend having the driver(s) on the dock and involved in monitoring the loading process. Unfortunately, a good number of thefts are “inside jobs.” Having the driver as an active participant provides another point of verification and helps to prevent thefts for both the shipper and the carrier.

- There is no such thing as a foolproof lock, but they do deter thieves who focus strictly on unlocked trailers. If ever stopped for extended periods, use of an air brake valve lock on the tractor (which secures the air valves and prevents the truck’s brakes from being released) and a king pin lock on the trailer or container are highly recommended.

- Place a seal on the trailer and container as well. Again, seals can be defeated, but intact seals generally indicate to drivers inspecting the load en route and personnel at the point of delivery that the shipment hasn’t been compromised. Be sure not to consistently match a specific type or color of seal with a particular commodity as thieves can (and do) figure out the pattern and use that knowledge to target specific loads.

Keeping freight secure while in transit

While the load is with the driver(s), many important practices must be followed.

- Freight is most vulnerable within 200 miles of pickup and delivery. Therefore, it’s critical for the carrier to have heightened monitoring for the first part of the freight move.

- Team drivers should be assigned to a high-value load. If a solo driver is assigned, he or she will likely have to make routine stops along the way. He or she should stick to a preplanned route that offers opportunities to stop at secure lots and facilities owned by the carrier.

- If the driver(s) has to stop at a non-carrier-owned location (such as a truck stop), they should park in a well-lit area and back against a building or pole to prevent rear doors from being opened.

- At each stop, the driver should communicate with dispatch and inspect the equipment to confirm that the load has not been compromised.

- Should the driver notice anything unusual or suspicious (such as tailing vehicles), he or she should call 911 immediately.

- Be sure that the carrier you work with has trailer security monitoring. A system that sends alerts when a trailer door has been opened or has been otherwise compromised is a valuable tool for thwarting thieves. This technology can determine if a trailer is loaded or empty and can track if a truck begins moving outside a predesignated route.

- If the truck or trailer should happen to break down while under the load (or if an emergency requires that the original driver be removed from the load), the carrier must have mechanisms in place to get the load moving again. In the case of a repair, the Operations team must help the driver identify the nearest repair facility and work with that facility to make sure high-standard security procedures are put in place to safeguard the load until the repair is made. If the driver experiences an emergency, the carrier should be able to direct the driver to the nearest, safest facility, where another driver can pick up the load. In either scenario, the new driver must be ready and able to move at least 200 miles out from the relay point before stopping again.

Freight security continues through delivery

Just because the driver makes it to the consignee doesn’t mean the job is done.

- Again, because of the vulnerability of the freight in the last miles of its move, the carrier should have a customer service team that pays closer attention to the load at this point in the move.

- For live unloads, include the drivers in the unloading process for the same reasons as stated previously regarding live loads.

- The drivers must also be aware of – and comply with – security procedures outlined by the consignee.

More Handoffs, More Risk: Intermodal Freight Requires Special Security Steps

The growth of intermodal freight movements means more thieves target the railroads as well. If managed correctly, freight can move securely and safely via this mode.

Intermodal freight security begins with load tender

An intermodal move starts the same way as a truckload move – with a customer sending the load information to the carrier. But the way to keep an intermodal load secure differs drastically from its counterpart mode, and those differences occur almost immediately.

- When the load is tendered, the carrier should begin communication with its railroad providers about the requirements for the particular load. Carriers should have procedures in place with rail providers for high-value loads. When containers arrive at a rail yard, they should be parked in a gated, well-lit area within eyesight of the yard’s office. The load should receive a security seal within 60 minutes of arrival and railroad security personnel should inspect it every three to four hours. The rail provider should also place a high-security lock on the container and follow a similar protocol.

- Make sure to specify that the load travels in a container instead of a trailer, which is more vulnerable. Trailers on rail cars are easier targets for thieves as they balance on the rear of the trailer to gain entry through the doors.

Freight security procedures are in place while cargo is in transit via rail

Special procedures are called for to make sure the container stays safe while in transit via rail.

- When possible, the load should sit in the bottom position of the well car (with other containers on top of it) during the railroad portion of the move.

- Along the route, the railroad provider should have checkpoints at which inspectors and rail police check each container to make sure none have been compromised.

- If the load needs to move from one railroad to another, again make sure that the trip can be done in one day, and insist your carrier use its own equipment.

- Anytime the load is scheduled to in-gate at a rail yard, the rail provider should send a report to the rail police, informing them of its impending arrival.

Freight security procedures in the delivery step of intermodal shipping

The final part of the intermodal move can provide the most risk. It’s important to keep security top of mind at every point in the move, especially in the final miles.

- The rules for delivery are similar to the rules for pickup and cross-town rail moves: Carriers MUST use their own equipment and go straight from the yard to the consignee.

- Be sure that the carrier you hire trains its drivers to stay aware and alert, since cargo thieves stalk freight coming off the rail. They must know to contact authorities if they even suspect a threat.

Layering security is the best line of defense against cargo theft

As you can see, there is no metaphorical silver bullet to ensuring freight security. Whether your cargo travels over-the-road or via intermodal, there are multiple security solutions for each phase of the move. Shippers and carriers who only use one security technique for each phase of the supply chain leave plenty of room for risk or error throughout. It’s the combination of actions that yields effectiveness in stopping cargo thefts.

Think about each of the solutions outlined previously as layers of security. When they are strategically layered one on top of the other, they cover up the holes that exist in the individual layers. That’s why it’s critically important that you work with carriers and intermodal providers to ensure there are multiple security checkpoints along every step in the supply chain. If you’re not layered in your efforts, you’re more likely to lose the load.

Shippers must leverage both high- and low-tech security solutions to keep freight safe

Technology has revolutionized the transportation industry over recent decades and has altered almost everything about the shipping process. So it shouldn’t come as a surprise that there are some sophisticated technological tools that play a role in keeping freight visible and safe. Working with a leader of in-transit risk management (such as Overhaul) provides an extra layer of security, including high-tech options such as these:

- Tracking devices in the load: You can hire a security company to embed a small tracking device right in your shipment. This differs from trailer-tracking technology and allows shippers to track their product even if the goods get separated from the trailer.

- Geofencing: The use of this technology is becoming more widespread. Essentially, the carrier puts a virtual “fence” around the route that the load is scheduled to travel from pickup to delivery. A tracking device allows the carrier and shipper (and railroad, if it’s an intermodal move) to follow the load along the route. All parties are alerted the moment the load veers off the route or the device itself is altered, enabling police to be immediately engaged in recovering the load.

- Electronic seal: These high-alert devices send an instant alert if the trailer or container seals are breached. In other words, if the doors are opened without authorization, the security team monitoring the shipment is immediately notified. Appropriate action can then be taken quickly.

As fantastic as these technological solutions sound, notice that the only technology absolutely necessary to carry out the procedures recommended here involves relatively low-tech systems: phones, computers, and perhaps in-cab communication devices. While technology can aid in keeping your freight secure, it’s by no means a replacement for basic, commonsense processes and good, old-fashioned communication. When your carrier has perfected these two elements, your merchandise will be far safer than anything being hauled by a company that relies mainly on the latest technology.

A culture of security should be just as important to your carrier as it is to you

Ensuring that your carrier follows the practices described here is a huge step toward tightening the security of your freight and minimizing risk. However, it’s only half the battle. If the carrier doesn’t wholeheartedly commit to instilling a culture of security among its associates, there will undoubtedly be gaps at other points in the supply chain. These include:

- Information technology: Be sure your carrier is diligent about protecting the information concerning you and your loads in its systems. Access to this data should be restricted. Only those who need the data to successfully execute the move should have access.

- Equipment maintenance: Part of keeping cargo safe is making sure that trucks, trailers and the places they park are secure. Look for a carrier that performs regular maintenance and inspections of security equipment, like intercoms, cameras, fence lines, gates and lights around its property.

- 24/7 customer service: If your carrier touts its customer service as top-notch but then leaves drivers high and dry after hours and on holidays, you’ve opened yourself up to risk. Most thefts happen on weekends, holidays and between 3 a.m. and 5 a.m. If a driver experiences a problem during these “off hours,” he or she can alert the company and resolve the issue before it grows into a situation that creates exposure for theft.

- Hiring the right people: Having the right person at the wheel is the biggest determinant for whether your load makes it to its destination safely and securely. You are entrusting that professional driver with your valuable product – a product your own customers are counting on receiving. That person should be intensely scrutinized before he or she joins the carrier’s team of professionals. That means thorough background checks, preemployment verification and clean driving records. As part of the background checks, carriers and intermodal providers conduct DOT drug tests. Drivers with addictions are at greater risk of being involved in cargo theft because of the need to finance their vices. A few carriers are now doing more in-depth drug screening by using hair testing, which can knock out potential drivers who passed their DOT urine test.

- Training, training and more training: Just because a driver has a CDL does not mean that person is ready to haul freight. If your carrier isn’t constantly assessing the performance of its drivers and helping them improve their skills, that’s a sign of a weak security culture. Even if they indicate no signs of less-than-stellar driving, carriers should have drivers participate in semiannual training sessions that include a focus on security measures and situational awareness.

- Constant communication: As with many endeavors, communication is the glue that keeps the pieces of the safety and security puzzle together. That means expectations must be clearly communicated both internally and externally. Sending drivers periodic alert messages keeping them aware of recent theft activity is a smart idea. Trucks equipped with cutting-edge in-cab technology also help drivers stay in constant communication with the company and the world around them.

- Relationships with security organizations: Ask your carrier about the relationships it has with different security and law enforcement organizations, including Customs and Border Patrol, the Transportation Security Administration, Federal Bureau of Investigation, Homeland Security, ASIS, CargoNet and local law enforcement. Having relationships with these entities can help to fast track an investigation should your cargo be stolen. Instead of waiting hours for your theft to be logged in the National Crime Information Center, it could take only minutes and make a big difference in whether the cargo is found.

Maintaining a high level of security must influence every single business decision a carrier makes. Ask your carriers the hard questions about their commitment to safe and secure operations, and be sure you get the right answers before that carrier is tendered a load.

Collaborate with supply chain providers to stay one step ahead of thieves

While safely and securely shipping your product from point A to point B will never be as carefree as it once was, you can increase security of your shipments. All it takes is engagement in the process. Work with your carrier to identify and close the gaps in your supply chain security. Collaborate with your internal team and with the providers who touch your freight. Finally, anticipate the continually changing security environment and be ready to adapt. You and your carriers will have to continually evolve your procedures to stay one step ahead of the thieves.

Contact us

Talk to an expert to learn more about Schneider's layered security solution to keep cargo and freight safe during transit and delivery.

Related resources

Drive your business forward

Sign up to receive our industry leading newsletter with case studies and insights you can put to use for your business.